Mission to Uphold

Narita’s Consistency

Kohei Tsuji

Joined NRTAS in 2018

- Engineering Services

- New graduate recruiting

Becoming a mechanic not for aircraft

but for specialized vehicles.

Ever since I was little, I liked fixing broken things and putting together plastic models more than playing games. I’m also the kind of person who loses all track of time once I start a project, so I felt like being a mechanic fit my personality.

I originally started studying to be an aircraft mechanic. I first heard about the job of working on the ground support equipment (GSE) that the ground handling team uses during my job search. The job seemed interesting and I switched career paths.

I chose NRTAS because it seemed exciting to be able to work at Narita, which attracts people from many different countries around the world.

Vehicle maintenance

to support aviation safety.

In my current job, I mainly inspect and maintain the large vehicles we call our main GSE, which are the high lift loaders that load customers’ luggage onto aircraft and the pushback tugs that push aircraft backwards to their designated position.

I also work on smaller towing vehicles called towing tractors and belt loaders used to load luggage and cargo directly into cargo holds.

I sometimes also have to run out and fix problems on the ramp when a working vehicle suddenly starts having a problem. For example, a high lift loader might break down while it’s in the middle of loading or unloading a departing or arriving flight. I really feel the pressure to be fast while fixing things when there’s no time to waste. It’s something I’m still not used to.

Having a huge fleet of vehicles

and overcoming challenges one by one.

A huge number of specialized vehicles are subject to inspections and maintenance. In terms of ANA’s vehicles, we perform maintenance on close to 500 vehicles a year. This scale really drives home that I’m working at an international airport.

My department also handles vehicles that belong to foreign airlines, so it’s close to around 1,000 vehicles when those are included. There are about 30 of us mechanics that work on them.

Some specialized vehicles have quite complex structures, and even highly experienced mechanics have a hard time figuring out where the cause of a breakdown is. Is the tip of the lever broken or is it the lever itself? Or is the problem actually somewhere else? For foreign-made vehicles in particular, the specs can be completely different than Japanese-made vehicles, with some even starting the engine in different ways.

And then the bigger the vehicle is, the bigger each of its individual parts are, too. This can also make it physically challenging to work on them.

Still, the harder a maintenance job is, the greater the satisfaction I feel when the repair work is all done. When I return a vehicle to its operator after having inspected and worked on it for several days and see it in operation, I feel quite proud thinking about how I was the one who fixed it. I sometimes also get told thank you directly, which is its own reward.

Making a team

with battle-hardened senior peers.

Mechanics often decide what to do and solve problems on their own. But even after working here for six years, there are still times when my technical skills aren’t enough to fully handle something on my own, or I run into a situation I’ve never experienced before. I get through these times by asking for help from my senior peers who have a lot more experience than me. And going beyond just technical support, co-workers who aren’t busy also help out others who are. We help each other out as one team, from young and mid-level to highly experienced mechanics. There are no generational walls between us as colleagues who share the same goal. This environment makes me feel reassured as I go about my daily work.

This work does not have a clear goal, when we reach a point where we know all the things we need to. Experience is what counts in this world, but even experienced mechanics gain various types of expertise by working with their hands and building up their experience little by little.

People might have the impression of mechanics silently going about their work, but we get along well with each other. I’d say NRTAS is more like a big friendly group, and we go out together outside of work, too. Making it easy for colleagues to talk to each other helps prevent maintenance mistakes, so I hope the students who join NRTAS also make a point of communicating with the people around them.

I think it’s important that all NRTAS employees, including the people working in maintenance, ground handling and operations and as ground staff, feel like they are all on the same team. Just my work alone does not accomplish everything we need to do.

My current work environment is enriching and allows me to improve my skills as a mechanic, but I’ve also recently become interested in gaining new experience in other departments, too. Among all the things that airport handling encompasses, I want to consider the work that we do from a high-level perspective and utilize my experience and knowledge to work toward further improving service quality for the ANA Group.

Day

Schedule

-

9:00

Arrive at work

After the morning meeting, I check who is assigned to do what work.

-

9:30

Get the vehicles to be inspected

I get the vehicles I will inspect that day from where they are stored.

-

10:00

Start tasks

After checking the notes and points to confirm before starting my tasks, I prepare to do the tasks.

-

13:00

Start tasks

I continue the tasks from the morning.

-

17:00

Finish tasks

I tidy up my work area, do the final checks and finish work.

Places

My favorite parts of Narita

-

Hikoki-no-oka (Airplane Hill)

Airplane Hill is located at the south end of Runway A, and like Sakura-no-yama Park, is a great place to watch aircraft take off and land up close. It has a heart-shaped monument said to bring good fortune when its bell is rung.

-

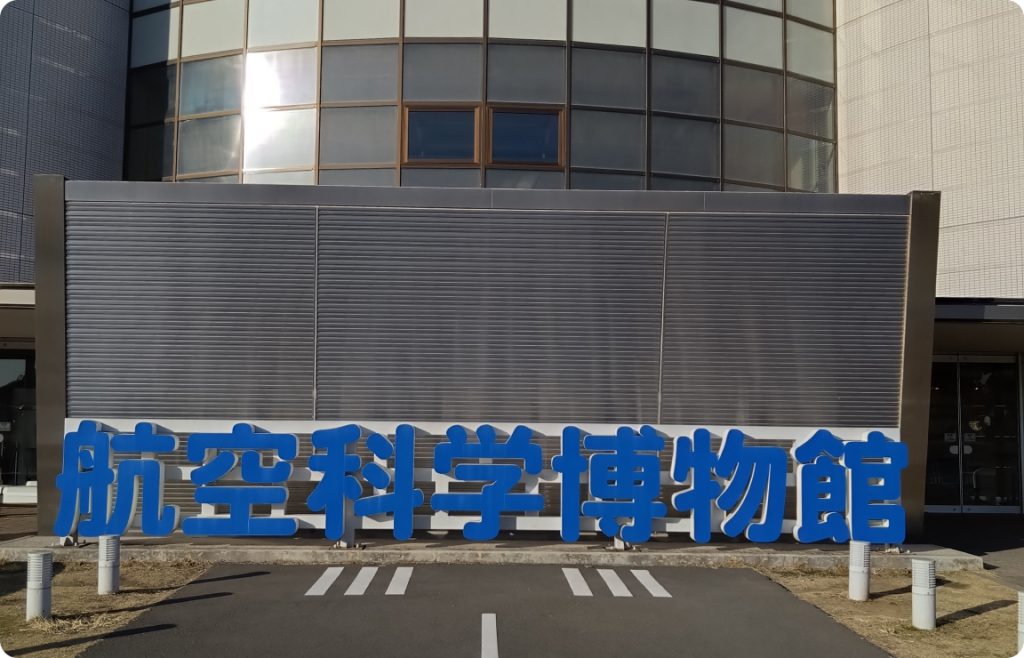

Museum of Aeronautical Sciences

Located near Hikoki-no-oka (Airplane Hill), the museum has aircraft-related exhibits with detailed explanations. The museum is also family friendly.

-

Sakura-no-yama Park

Located at the south end of Runway A, you can watch aircraft take off and land up close at the park. The cherry trees bloom in spring, and many people come here to photograph aircraft with the cherry blossoms.

Leading ANA’s international flight operations, NRTAS is aiming for new heights.

NRTAS will create the new era.